About our Business

We have in-house designer, parts processing,

assembling, wiring departments,

enabling seamless product manufacturing processes.Furthermore, we do not

operate on a mass production model. Instead, we customize products according

to specific customer requirements. Leveraging our solid foundation and extensive

application experience, we flexibly respond to customer needs, thereby enhancing

customer satisfaction. With nearly 50 years of experience, we have accumulated rich

expertise in the research and development and manufacturing of various fixtures, tools,

and specialized equipment. We have a proven track record of providing equipment for

various processes in semiconductors, LCDs, electronic components, and automotive-related

products, and are widely recognized by numerous companies for our "unique" manufacturing

solutions capabilities and technical expertise

Production Equipment Cases

Directly with our clients and provide

customized products to meet their specific needs, including semiconductor-related products,

circuit board-related products,

automotive parts-related products, office automation equipment-related products, and electronic

component-related products.

We propose equipment solutions.

Automotive-related equipment

Door switch assembly machine, valve

assembly inspection device, interior light assembly machine, internal inspection device,

triangular cutting machine, gasket installation machine, press-fitting machine

Connecting rod measuring machine, throttle body assembly equipment, water sprinkling

installation production line, cylinder head nut hot insertion machine, bushing press-in

machine, air tightness inspection machine, flow detection machine

Automatic screw driving machine, automatic BOLT press-in machine, voltage angle

inspection machine, automatic multi-angle glue applicator, function inspection machine,

air pressure inspection machine, laser marking machine

Component installation omission inspection machine

Semiconductor-related equipment

Molding equipment, marking equipment,

stripping and cleaning machine, lead processing machine, testing equipment,

cutting/bending equipment, automatic soldering machine

Electronic related equipment

Board inspection equipment, double-sided

tape pasting machine, automatic terminal insertion machine, characteristic inspection

machine, withstand voltage and conductivity inspection machine

OA-related equipment

Ink cartridge assembly machine, oiling

machine, laminating machine, UV irradiation curing machine, shipping packaging machine

Liquid crystal related equipment

Glass composite equipment, misalignment

inspection equipment, backlight sealing machine, lighting inspection equipment,

substrate conveying equipment

Optics-related equipment

Lens injector, testing machine, optical

axis adjuster, installation, picking, and fixtures for each project

Other

Various loaders/unloaders, appearance

inspection devices

Workshop

We have domestic factories and overseas group

factories, which enables us to independently produce a large proportion of products and meet

short delivery times.

1st Floor of the Factory <Parts Processing

and Production Department>

The production of high-precision custom

machines starts with the processing of internal parts.

By processing each part manually, we can provide parts with higher precision.

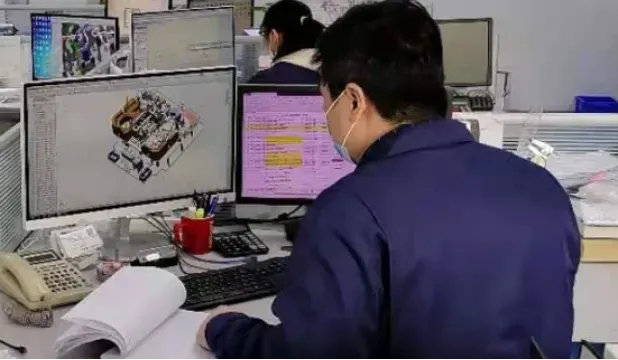

2nd Floor of the Factory <Design

Department and Engineering Department (Assembly, Wiring)>

Second floor design and assembly

department.

Our design department is dedicated to strengthening the integration of mechanical and

electronic technologies,

continuously conducting cutting-edge research and development.

Achieve higher reliability and functionality, we have cleanrooms and coordinate

measuring machines for rigorous quality control.

Equipment Assembling and Wiring

Shenzhen factory has 2000㎡ assembly space,

capable of handling lines up to 50m long.

Japanese technicians are stationed there, enabling the production of equipment identical to that

in Japan.

Assembly and Wiring Center 1

Assembly and wiring

With a 2000㎡ assembly space

Capable of handling lines up to 50m in length

Japanese technicians are stationed here

Able to manufacture equipment identical to those in Japan

Assembly and Wiring Center 2

Assembly and wiring

It has an assembly space of 2000

square meters.

It can handle lines up to 50 meters long.

There are Japanese technicians stationed here.

It can manufacture equipment that is the same as those in Japan.